Condition monitoring of conveyor systems for safe, fault-free operation

Artical by Heiko Bach is Business Development Manager for Heavy Industry at the Schmersal Group

Safe, fault-free operation of conveyor systems is an essential factor when it comes to production efficiency and profitability. The Schmersal Group offers intelligent components and systems for safe and efficient conveyor systems. These also include solutions for condition monitoring – the capture and evaluation of process and diagnosis data from system components to enable predictive maintenance and to increase availability.

Raw materials are often transported in bulk directly from mines for processing or loaded onto rail vehicles or vessels for onward transport. Steel belt conveyor systems help to bridge large distances of several kilometres, with conveying speeds of up to 10,000 t/h.

Process safety is where conveyor belt operation starts and ends. Operating companies have an economic interest in fault-free operation, 24 days a week, 365 days a year. Faults, interruptions or even failures of conveyor systems can have major consequences – from delays in delivery and short-term supply bottlenecks to significant production interruptions, such as in cement, power and steel plants, which can come with high financial losses.

Over recent decades, Schmersal [1] has steadily expanded its range of products and systems for process safety and personal protection in bulk materials handling (Figure 1).

Modular switchgear platform supports a range of applications

One such example is the modular HDS switchgear series, which is designed for use in heavy industry. It unites a number of functions into a single platform, allowing it to be used for a range of different applications. Its key features include the uniform housing concept, which comprises two versions – a plastic version (thermoset) and a grey cast iron version

The plastic version is resistant to aggressive media and especially suitable in port logistics applications and loading and unloading operations. It is also ideal for the agricultural industry in the processing of fertilisers and phosphates. The robust grey cast iron version is particularly suitable for use in mining.

The devices also come in two basic functional versions: emergency stop, designed as a pull-wire emergency switch (Figure 2), and for position monitoring. The basic switch on the position monitoring version can be flexibly combined with a range of actuation elements. Typical application areas include emergency-stop shutdown, belt misalignment monitoring on conveyor belts, end position monitoring in steel making and level monitoring in material silos.

Belt misalignment monitoring is an important function in process protection of conveyor systems. Conveyor belts can run out of their designated track, causing considerable damage. Belt alignment switches (Figure 3) are used to detect any belt misalignment at an early stage. Smaller deviations trigger a pre-warning, while greater deviations trigger a shutdown. The pre-warning gives the conveyor system owner’s maintenance department enough time to prevent unscheduled production shutdowns and rectify faults. Belt alignment switches thus help to reduce failures and downtimes, and ensure greater system availability.

All basic versions of the HDS series can be optionally connected to the Dupline installation bus (Figure 4), allowing the switches to be interconnected quickly, connected in series and thus enabling easier transmission of diagnosis data.

Wireless data transmission for expansive conveyor systems

Working in cooperation with its system partner Aconno [2], the Schmersal Group is currently developing a new idea in the form of an Industry 4.0-capable switch. On expansive conveyor systems, this new switch will enable wireless transmission of status information data over several kilometres. The benefit of this is easier monitoring, more rapid rectification of faults and, in turn, better process protection. It will be possible to monitor all switching operations in real time and online via a web browser on a PC or smartphone. The data from the cloud will be transmitted directly to the control centre or a smartphone in the hands of maintenance and service technicians at site using the web interface or APP.

“The devices also come in two basic functional versions: emergency stop, designed as a pull-wire emergency switch (Figure 2), and for position monitoring. The basic switch on the position monitoring version can be flexibly combined with a range of actuation elements. Typical application areas include emergency-stop shutdown, belt misalignment monitoring on conveyor belts, end position monitoring in steel making and level monitoring in material silos.”

Process protection for conveyor belts with online monitoring

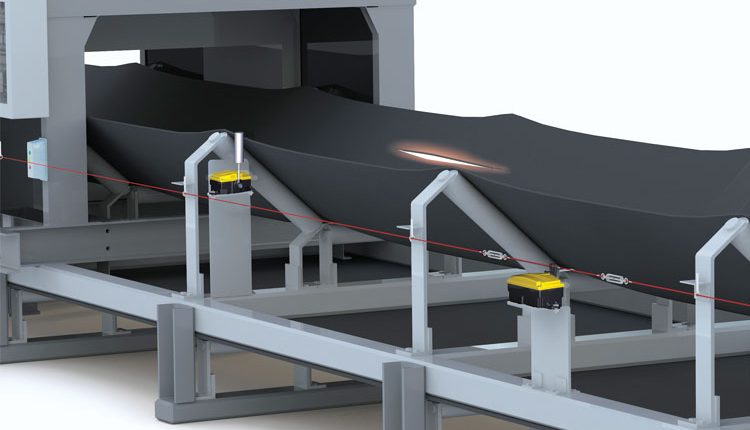

In addition to the stated components and systems designed to boost machine safety and process protection, Schmersal is now able to offer a fully automated online monitoring system for existing or new conveyor systems through its system partner ROXON [3]. The HX270 enables optical 3D belt surface sampling in real time both for the material side and running side of the conveyor belt.

With high-speed precision scanning using novel 3D image analysis algorithms, the system can detect any change or damage to the belt surface fully automatically, 24 hours a day. In addition, optional belt thickness measurement gives the system a full-fledged condition monitoring solution for smart maintenance and servicing.

The HX270 intelligent system automatically records existing belt damage and alerts the user if new damage is detected or existing damage worsens to become critical. In this latter case, the conveyor belt is stopped automatically. The damage and wear data are stored in a database. Users can gain physical access with just a few clicks of the mouse and an automated conveyor belt control system so that they can inspect and repair the damage.

Conclusion

Conveyor systems are an essential tool for materials flows in the global bulky materials industry, whether in the mining of raw materials, gravel and cement plants, landfill or recycling sites or the movement of seeds and animal feed. Just as varied as the range of applications is Schmersal’s range of systems and solutions for machine safety and process safety in the conveyance of bulky materials, optimally covering the entire field of condition monitoring.

“In addition to the stated components and systems designed to boost machine safety and process protection, Schmersal is now able to offer a fully automated online monitoring system for existing or new conveyor systems through its system partner ROXON [3]. The HX270 enables optical 3D belt surface sampling in real time both for the material side and running side of the conveyor belt.

With high-speed precision scanning using novel 3D image analysis algorithms, the system can detect any change or damage to the belt surface fully automatically, 24 hours a day. In addition, optional belt thickness measurement gives the system a full-fledged condition monitoring solution for smart maintenance and servicing.

Notes:

- Process safety is where conveyor belt operation starts and ends.

- The EX-I-ZQ900 pull-wire emergency switch is used on conveyor systems in areas at risk of explosion, where there might be the need to trigger the emergency stop command at any point along the route of the wire.

- The modular HDS switchgear platform, is configured here as a belt misalignment switch for conveyor belts.

- Schmersal offers either Dupline-Safe or Dupline as a fieldbus solution for the networking of switchgear devices over large distances. This helps to ensure accurate diagnosis and safe shutdown

About the Author

Heiko Bach is Business Development Manager for Heavy Industry at the Schmersal Group.

Website: https://www.schmersal.in/