The construction industry is one of the largest employment generators worldwide, yet it remains among the most hazardous sectors. From high-rise buildings and infrastructure projects to industrial plants and residential developments, construction sites are inherently dynamic environments involving heavy machinery, working at heights, electrical systems, and multiple trades operating simultaneously. Ensuring construction safety and the safety of workmen at site is therefore not merely a regulatory requirement but a moral, social, and economic imperative.

Understanding the Risks on Construction Sites

Construction sites are exposed to a wide spectrum of risks—falls from height, struck-by incidents, electrocution, caught-in or between machinery, and exposure to dust, noise, and hazardous substances. Temporary structures, constantly changing layouts, and time pressures further increase vulnerability. Many accidents occur due to inadequate planning, unsafe work practices, poor housekeeping, or lack of awareness among workers. Recognising these risks at the planning stage is the first step towards effective safety management.

Safety by Design and Planning

Safety must begin at the drawing board. Incorporating safety considerations during the design and planning phase significantly reduces on-site risks. This includes safe access routes, proper material handling plans, structural stability during construction, and provisions for temporary supports and scaffolding. Risk assessments, method statements, and job safety analyses help anticipate hazards and define preventive measures before work begins. A well-planned site layout with clear demarcation of work zones, walkways, storage areas, and emergency exits contributes immensely to accident prevention.

Role of Personal Protective Equipment (PPE)

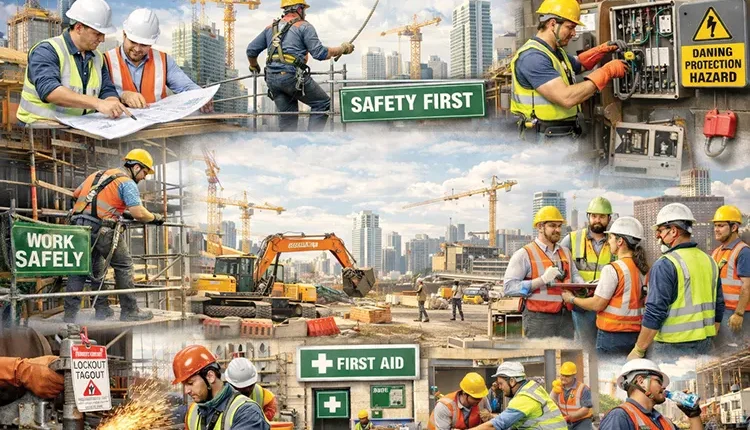

Personal Protective Equipment forms the first line of defence for workmen against site hazards. Helmets, safety shoes, reflective jackets, gloves, eye protection, earplugs, and fall arrest systems are essential depending on the nature of work. However, merely providing PPE is not enough. Proper selection, correct usage, regular inspection, and replacement of worn-out equipment are equally important. Training workers on why and how PPE should be used ensures higher compliance and effectiveness.

Working at Height and Fall Prevention

Falls from height remain one of the leading causes of fatalities in construction. Activities such as scaffolding, formwork, roofing, and structural erection demand stringent fall prevention measures. Guardrails, safety nets, secure ladders, and certified scaffolding systems must be installed and regularly inspected. Full-body harnesses with lifelines should be mandatory where collective protection is not feasible. Equally important is ensuring that work at height is carried out only by trained and authorised personnel.

Machinery, Equipment, and Tool Safety

Construction sites rely heavily on machinery such as cranes, hoists, concrete mixers, excavators, and power tools. Unsafe operation, lack of maintenance, or unauthorised use can lead to serious accidents. All equipment should be certified, periodically inspected, and operated strictly as per manufacturer guidelines. Operators must be adequately trained and licensed. Lockout and tagout procedures during maintenance, along with proper guarding of moving parts, enhance equipment safety significantly.

Electrical Safety at Site

Temporary electrical installations are common on construction sites and pose a high risk if not managed correctly. Use of proper cables, weatherproof distribution boards, residual current devices (RCDs), and effective earthing is critical. Cables should be routed to avoid mechanical damage and water ingress. Regular inspection of electrical tools and systems, along with clear labelling and isolation procedures, reduces the risk of electrocution and fire.

Training, Awareness, and Safety Culture

A strong safety culture is built through continuous training and awareness. Induction programmes for new workers, toolbox talks, safety drills, and periodic refresher training help reinforce safe work practices. Visual aids such as safety signages, posters, and colour coding act as constant reminders. Encouraging workers to report unsafe conditions and near-misses without fear fosters collective responsibility and proactive safety behaviour.

Health, Welfare, and Well-being of Workmen

Safety extends beyond accident prevention to overall health and well-being. Adequate sanitation, drinking water, rest areas, first-aid facilities, and access to medical care are essential at construction sites. Managing exposure to dust, noise, vibration, and hazardous substances protects workers from long-term occupational illnesses. Fatigue management through reasonable working hours and rest breaks also plays a vital role in preventing errors and accidents.

Monitoring, Compliance, and Continuous Improvement

Effective safety management requires constant monitoring and enforcement. Regular safety audits, inspections, and compliance checks ensure adherence to statutory norms and project-specific safety plans. Learning from incidents and near-misses enables continuous improvement. Leadership commitment, visible involvement of supervisors, and integration of safety into daily operations transform safety from a checklist activity into a core organisational value.

Conclusion

Construction safety and the safety of workmen at site are inseparable from project success. A safe site not only protects lives but also improves productivity, quality, and morale while reducing delays and costs. By adopting a holistic approach encompassing planning, equipment, training, health, and culture, the construction industry can move towards safer, more sustainable work environments—where every worker returns home safely at the end of the day.