The annular plate region of aboveground storage tanks is critical to its integrity, since it has the highest mechanical stress. At the same time, sagging of the tank can open it seal and expose the underside to air and water to start corrosion. If left unchecked, the tank may catastrophically fail, releasing its content in a short time.

Challenges in Storage Tank Annular Plate :

- Annular plate region is prone to accelerated corrosion due to the additional stresses caused by the weight of the tank wall and higher possibility of water entrapment under the annular plate. Thus conventional inspection techniques fall short in capturing desired data.

- Repairs in this region demand replacement of the entire annular plate and this leads to long shutdown of the tank, and often lead to failures without prior indications.

- Shutdown for carrying an inspection leads to time loss in emptying & refilling of tank and considerable amount of revenue losses to asset owners.

So how are we to inspect storage tank annular plate without a shut down?

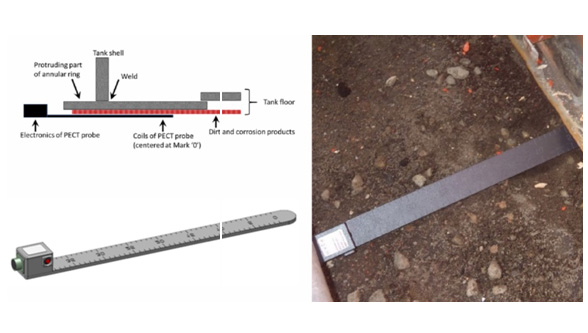

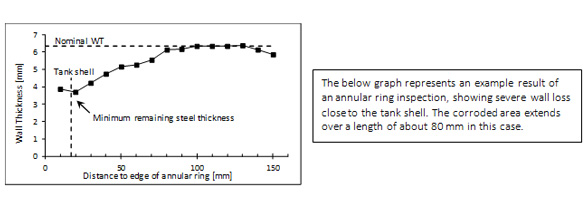

A flat PECT probe is inserted underneath the tank floor for in-service inspection. Such inspection is of great value, as it can help to extend the intervals between out-of-service inspection.

What is Pulsed Eddy Current (PEC)?

Pulsed Eddy Current (PEC) is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron. It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area.

Advantages of PEC technology in Tank Annular plate inspection:

- PEC sensors are designed to tolerate lift-off between the surface under test such as air, soil, water, concrete, asphalt, and corrosion products.

- No surface preparation required. PECT is powerful enough to measure through thick layers of corrosion products (iron oxides) underneath the tank floor.

- Compact magnetic field increasing defect sensitivity.

- Measurement accuracy of ±10% of measured wall thickness

- PEC flat probes can be inserted underneath the annular ring of a tank floor thus inspection can be performed during in-service conditions, eliminating shut down.

- Battery powered instrument, thus perfect for remote locations.

- PEC is one of the fastest screening tool available for Storage Tank Annular plate inspection.

Standards guiding PEC Inspection : ISO 20669