Exposures to welding fumes and gases should be controlled as much as possible by following safe practices and good occupational hygiene measures. It is desirable to wear appropriate personal protective equipment. Suitable firefighting appliances also should be placed near to the place where welding & cutting operations are being carried out. – R. R. Nair

1.0 INTRODUCTION

Welding, cutting and allied operations take place in a wide variety of locations under many different conditions. These operations are carried out in factories, building construction sites, pits, vats, mines, tanks, ship compartments and literally everywhere that metals are joined or cut. It is a major industrial process, which uses heat and / or pressure to join metals. Among the different welding techniques, arc welding has become the most widely used. The accidents happening during the welding process are very typical and involve number of injuries. Hot metal slag and spatter often can be dangerous to the operator and to the surroundings. Many welding, cutting and allied processes produce fumes and gases which may be harmful to workers health. In confined spaces the gases might displace breathing air and cause asphyxiation. Excess noise is a known health hazard in welding, cutting and allied operations. Arc welding emits harmful rays like ultraviolet rays and infrared rays and fumes which may cause unpleasantness.

This article will focus on some of the hazards involved in welding & cutting operations and precautions to be taken to mitigate them. Before we discuss the various hazards involved in welding & cutting operations, it will be worthwhile to discuss briefly on some of the popular methods followed for welding & cutting operations.

2.0 METHODS OF WELDING

The methods of welding can be classified mainly into two viz.: (i) Oxy-Acetylene Welding and (ii) Arc Welding, which are dealt in brief below.

2.1 Oxy-Acetylene Welding

Oxy-acetylene welding is a very common welding process. The combination of oxygen and acetylene produces a flame temperature over 3100O C making it ideal for welding & cutting. Oxy-acetylene welding is also known as oxy-fuel welding or oxy welding or gas welding and oxy fuel cutting in which fuel gases and oxygen are used to weld and cut metals. In recent decades, oxy-acetylene has been less widely utilized in industrial operations as other specially devised technologies have been adopted. However, it is widely used for welding pipes and tubes, as well as repair work. It is also frequently well suited, and favoured for fabricating some types of metal-based art work. It may be kept in mind that oxy-acetylene welding has an advantage over electric welding and cutting processes, in situations where accessing electricity would present difficulties.

In oxy-acetylene welding, the flame produced by the combination of the gases, melts the metal faces of the work pieces to be joined, causing them to flow together. A filler metal alloy is normally added and sometimes be used to prevent oxidation and facilitate the metal union.

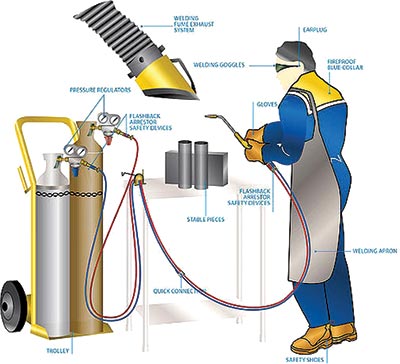

The apparatus used in gas welding consists basically of an oxygen source and fuel gas source (usually cylinders), two pressure regulators and two flexible hoses (one of each for each cylinder) and a torch (See Fig 01 & 02). Usually welding tip is mounted on the end of the torch handle and fuel & gas mixture pass through it to feed the flame. Welding tips have only one hole, while cutting tips have a centrally located hole with a number of smaller holes located around it, in a circular pattern. During cutting, the oxygen comes from the centre hole and preheat flames come from the holes around the centre hole. Now torches are available in various designs incorporating many safety devices (See Fig 03).

Oxygen Cylinders

The gaseous oxygen is normally compressed into cylinders. The cylinder when full, normally contain oxygen at a pressure of 139.2 Kg/cm2. Oxygen is colourless and odourless. It supports and promotes combustion, but is not flammable. For identification, oxygen cylinders are painted black.

Acetylene Cylinders

Acetylene is the fuel gas normally used for welding and cutting. It is produced by the chemical reaction between water and calcium carbide. It is a highly combustible gas having an explosive range when mixed with air or oxygen in the proportion from 2% to 82%. Acetylene may be readily identified by its characteristic pungent smell. Acetylene cylinders are painted maroon for identification. When acetylene is mixed with oxygen from cylinder in the ratio of one to one, a flame having a temperature of approximately 3140O C, is obtained on ignition of the mixed gases at a blow pipe nozzle.

The acetylene cylinders are charged at a pressure of 17.57 Kg/m2. At the base of the cylinder and on the cylinder valve, a bursting disk safety plug device is fitted to guard against excessive built up of pressure within the cylinder. It may be kept in mind that the user should under no circumstances tamper with these fittings. Copper pipe must never be used for coupling, because, the copper in contact with acetylene may form a dangerously explosive compound of copper acetylide.

2.2 Arc Welding

There has been a tremendous growth in the field of arc welding. Resistance spot welding is one of the oldest of the electric welding process in use by Industry today. The weld is made by a combination of heat, pressure and time. In arc welding, the arc is struck between an electrode and workpieces connected to an AC or DC supply. The temperature is around 4000O C when the workpieces fuse together. Usually molten metal is added to the joint, either by melting the electrode itself or by melting a separate filler rod, which is not carrying current.

Conventional arc welding is done manually by means of covered or coated consumable electrode hand-held in an electrode holder. However, many fully automatic electronic welding process are also carried in industry. Arc welding use a continuous electrical discharge (an electric arc) to generate high temperature of 3000O C to 30,000O C. The electric arc is maintained at the gap between the electrical conductors, i.e. the electrode and the workpiece. The arc can be maintained and moved to melt part of the workpiece and fill on filler metals as required to form a weld.

Welding fumes and gases are produced during the welding process as by products in the form of a welding plume. The heat and ultraviolet radiation from the welding arc also generate potentially harmful gases in the surrounding air. Welders and other workers nearby are exposed to all of these substances.

It is estimated that about 80% of all welding is accounted for by three major arc welding methods, viz.: (i) Shielded Metal Arc Welding (ii) Metal Inert Gas Welding and (iii) Tungsten Inert Gas Welding. These methods are used to weld four major types of metals, viz.:

(i) Mild Steel (ii) Stainless Steel & High Alloy Steels and (iii) Aluminium & Galvanised Steel.

Shielded Metal Arc Welding

Shielded Metal Arc Welding (SMAW) is the most common arc welding process. It is also known as Manual Metal Arc Welding. It uses a short length of consumable electrode, which melts as it maintains the arc. Metal with characteristics similar to the metal being welded is melted off the electrode and carried across the arc to become the filler metal of the weld. The electrode is fed into the arc as fast as it melts to maintain a constant arc length. The electrode is coated with a complex mixture of chemical compounds, which perform important functions in the welding process. The principal role of the coating is to release a blanket of inert gas such as carbon dioxide to keep air out of the arc zone to prevent oxidation and contamination while welding is in progress. The composition of the coatings varies with the metal being welded.

Metal Inert Gas Welding

Metal Inert Gas Welding (MIG) uses an uncoated consumable wire that is fed continuously down the middle of the welding torch. A ring like tube around the wire transports an inert gas such as argon, helium or carbon dioxide from an outside source to the arc zone to prevent oxidation of the weld. Flux Cored Arc Welding (FCAW) is a variation of MIG welding. This process uses a hollow consumable wire, the core of which contains various chemicals that generate shielding gases and strengthen the weld.

Tungsten Inert Welding

Tungsten Inert Gas Welding (TIG) uses a non-consumable tungsten electrode, which maintains the arc and provides sufficient heat to join the metals. If filler metal is needed, it is added in the form of a rod held close to the arc, so it will melt and be deposited at the weld. Externally supplied shielding gases may or may not be used in TIG, depending on the metal being welded.

3.0 HAZARDS IN WELDING

The hazards involved in welding and cutting operations may be divided into two groups, viz., (i) Fire and Explosion Hazards and (ii) Health Hazards, which are dealt below:

3.1 Fire and Explosion Hazards

Welding, cutting and allied processes produce molten metal, sparks, slag and hot work surfaces. These can cause fire or explosions if precautionary measures are not followed. During the operations, sparks and spatter fly-off. Flying sparks are the main cause of fires and explosions in welding and cutting. The sparks and molten metal can travel greater distances when falling. It may be kept in mind that the sparks can travel up to 36 feet from the work area. Sparks can even pass through or lodged in cracks, pipe holes, and other small openings in floors, walls or partitions, and roofs leading contact with combustibles. The combustible material inside a workplace or buildings include: wood, paper, rags, clothing, plastic, chemicals, flammable liquids and gasses & dusts. Parts of workplaces or buildings such as: floors, partitions, and roofs may also be combustible. The typical combustible materials outside workplaces or buildings include dry leaves, dry gas, and bush.

3.1.1 General Precautions

Although low voltage current is used in normal arc welding, welding currents are high, due to the usage of equipment operated at power supply line voltage. The risk of electric shock should not be ignored, especially in cramped spaces or in insuring positions. Therefore, before welding commences, the earthing installation on arc welding equipment should always be checked. Cables and connections should be sound and of adequate capacity. A proper earthing clamp or bolted terminal should always be used. Where two or more welding machines are earthed to the same structure, or where other portable electric tools are also in use, earthing should be supervised by a competent person.

The working position or place used for welding and cutting operations should be dry, secure and free from dangerous obstructions. A well-arranged, well lighted, properly ventilated and tidy workplace is important. If the work is carried out in confined spaces or dangerous positions, additional electrical protection can be installed in the welding circuit, ensuring that only extremely low voltage current is available at the electrode holder, when welding is not taking place.

Jaws and connections of electrode holders should be cleaned and tightened periodically to prevent overheating. Provision should also be made to accommodate the electrode holder safely when not in use by means of an insulated hook or a fully insulated holder should be used. Plastic tubes and PVC-covered cables should be used for all supplies from the transformer to the electrode holder.

Dragging of cable and plastic gas supply tubes across hot plates or welds must be avoided. Heavy articles left hot on completion of welding should always be marked “hot” as a warning to other workers. Rubber tubes and rubber covered cables must not be used anywhere near the high-frequency discharge, because the ozone produced will rot the rubber.

Dirt and metallic dust can cause a breakdown in the high-frequency discharge unit, which should be cleaned regularly by blowing out with compressed air.

In high pressure gas welding installations, both the oxygen and the fuel gas, such as acetylene, hydrogen, propane supplied to the torch are obtained from cylinders, in which they are stored at high pressure. The hazards encountered and numerous precautions required in using compressed gas cylinders are dealt in details in the Indian Gas Cylinders Rules, 2005. The welders and supervisors are advised to follow these provisions. In addition, the following precautions should be scrupulously observed during the gas welding and allied operations:

- The regulators fitted to the cylinders should be designed for the gas in use. It may be born in mind that an acetylene regulator should not be used with hydrogen or coal gas.

- Oxygen and acetylene cylinders must be stored separately and only on fire resistant premises devoid of flammable materials. In case of fire, they may be readily removed.

- The colour coding in force or recommended for identification of cylinders and accessories should be followed. For example, oxygen must be kept in black cylinders with blue hose, acetylene cylinders in maroon with red hose (See Fig 04), and other combustible gases in red cylinders. The Indian Standard IS 4379 (1981): Identification of contents of industrial gas cylinders, recommends colour for various cylinders, which may be followed.

3.1.2 Backfires and Flashbacks

Backfires and flashbacks are the most common hazards in welding and cutting operations. Backfire occurs in the torch itself and reaches only into the welding or cutting torch tip and it never travels beyond the torch. However, the flashback is the most dangerous type, and in this case, the flame clearly reaches the fuel gas supply source through the cutting torch and hoses. The flame burns back into or even beyond the mixing chamber and may travel through the hoses.

It may be noted here that if backfire occurs and if the torch is not shut off immediately, and if the conditions causing the backfire are not corrected, then flashback occurs. In case of flashback, the flame action has an explosive violence. A flashback can occur in oxygen hose as well as in acetylene hose also.

When conducting oxy fuel cutting and welding operations, operators can experience backfires or flashbacks. Check valves and flashback arrestors are some of the safety devices used for protecting workers involved in oxy fuel cutting and allied operations. A check valve is a device that is designed to prevent unintentional back flow of gases. A flashback arrestor (flame arrestor) is a device that prevent the propagation of flame upstream. Note that these devices reduce the volume of gases available at the tip/nozzle which in turn arrest the potential backfires and flashbacks. Typical check valves and flashback arrestors are illustrated in figure 3.

3.1.3 Fire Preventions

As the chances of fire during the gas welding operations are very high, attention should be paid to surrounding walls, floors, nearby objects or waste materials. All combustible materials should be removed or adequately protected by sheet metal. It may be kept in mind that tarpaulins should be never used for protecting combustible materials. Wooden structures should be avoided or protected. If welding operations are carried out on wooden floors, it should be covered or wetted thoroughly. If flammable materials are stored in adjoining rooms or on the floor below the work area, they should be removed to a safe position. The workplace and surrounding area must be clean of anything which may catch fire from welding vessels which have contained flammable substances. Alloys rich in magnesium or other combustible metals should be kept away from the welding flame.

If a fire risk is present, a responsible person should keep the welding site under observation for at least an hour after the completion of the work. As many metals, clothing and other materials become actively combustible in the presence of oxygen, gas welding oxygen should never be released into the air in a confined space. Gas cutting operations should never be undertaken in a confined space without proper ventilation.

Suitable fire extinguishing apparatus should be always kept at hand. In case of low pressure plant using an acetylene generator, fire buckets of dry sand should be made available. Fire extinguishers of dry powder or carbon di-oxide, can be used for fire prevention. In any case water must not be used for fire prevention.

3.1.4 Explosion Preventions

The chances of an explosion during the gas welding is high. Explosions can occur when acetylene gas is present in air in any proportion between 2% and 80%. Thus, adequate ventilation should be provided when acetylene cylinders are used for gas welding. Welding and cutting can cause explosions in spaces containing flammable gases, vapours, liquids or dusts.

All arc welding operations should be screened to protect other persons working nearby. Where the work is carried out at fixed benches or in welding shops, permanent screens should be erected where possible, otherwise temporary screens should be used. The screens should be opaque of sturdy construction and of a flame resistant material.

The use of black paints for the inside of welding booths has become an accepted procedure, but the paint used should produce matt finish. Adequate ambient lighting should be provided to prevent eye strains leading to headaches. Welding booths and portable screens should be checked regularly to ensure that these are giving adequate protection to the persons working nearby.

The precautions to be taken during arc cutting operations do not differ materially from those required in arc welding. However, since the currents used are generally higher, more and heavier protective clothing is generally required. When the carbon arc cutting method is used, a good helmet is to be preferred to a hand shield. Spats of leather or asbestos should be worn to protect the feet from falling molten metal.

3.2 Health Hazards

Fluxes containing fluorides are frequently used in silver brazing and welding of aluminium, magnesium and alloys. The hydrogen fluoride, if produced in sufficient concentration, will be irritating and injurious to the welders. Some silver brazing may contain cadmium. Materials which have been coated with toxic materials such as lead, cadmium may produce harmful effects when welded by any process. The brown cadmium fumes are extremely dangerous producing severe and fatal lung damage on short exposure. Metal fumes fever, may follow exposure to zinc fumes resulting from operations on galvanized materials, brass or bronze and at times from the use of bronze filler metal. Welding on tanks and containers of any sort from which the contents have not been thoroughly removed may introduce a series of hazard by volatilization or decomposition of the residue.

3.2.1 Heat and Burns

Burns of the eyes and exposed parts of the body may occur owing to spatting of incandescent metal particles. Intense radiations from the flame and incandescent metal in the weld pool can cause discomfort to the operator and person in the vicinity of the operation and therefore precautions are necessary. Excessive exposure to ultraviolet radiation may also cause overheating and burning of the skin and the face, nape of the neck and other exposed parts of the body which should be correspondingly protected. A high-frequency spark used to indicate the arc can cause small, deep burns of concentrated at a point on the skin. Burns due to contact with hot materials may also be sustained, generally through lack of care, or failure to wear proper protective clothing, free from oil and grease. The workplace must be tidy and unencumbered with flammable materials. Hands and forearms should be protected by suitable gloves or sleeves. In overhead welding, a protective cape and cap are necessary.

3.2.2 Eye Injuries

There are two types of radiations, viz.:

(i) Ionizing (such as x-rays), and (ii) non-ionizing (such as ultraviolet, visible light or infrared). Non-ionizing radiations are associated with welding operations.

In welding and cutting operations, intense radiations are emitted by heated solids or gases. Strong ultraviolet rays are capable of causing severe inflammations similar to sun burn in the eyes, and on the exposed skin. Extremely intense visible rays may cause eye strain or even temporary blindness. Infrared rays are not absorbed but will penetrate the eye. They are suspected to be the cause for cataracts, retina injuries as well as opacity of the cornea. As the intensity of these radiations depend upon the temperature of the welding source. The danger from arc welding is greater than that from gas welding or cutting.

The light emitted by an electrode arc contains a high proportion of ultraviolet radiation. Most arc welding & cutting processes; laser welding & torch welding; cutting & brazing; or soldering produce quantities of radiation requiring precautionary measures. Some processes, such as resistance welding and cold pressure welding, ordinarily produce negligible quantities of radiant energy.

Ultraviolet & Infrared Rays

Ultraviolet rays are to be feared not only because they are invisible, but also because we, human beings do not have sense organs to detect them. On absorption of these rays, the lens may fluoresce, i.e., shine in the dark, which may disturb vision. Ultraviolet radiations may affect the eye in a manner similar to sun burn. The common phenomenon of “Arc Eye” can be attributed to these rays.

An exposure of the rays for a few seconds, may produce, a feeling of sand in the eyes with pain, watering of the eyes and possibly headache and these symptoms may develop after four to eight hours. This is known as “Arc Eye”. Recovery is complete in 24 to 48 hours and no permanent effects need be feared. All welders should be protected from the rays produced by the welding arc by the use of proper hand-shield or goggles fitted with the proper grade coloured filter glasses (See Fig 05).

Infrared rays are commonly called heat rays, because when they encounter any material which they cannot penetrate, they are absorbed and changed into heat waves. These rays produce the sensation of heat when they fall upon the skin. Prolonged exposure of the skin will result in sun burn condition. Medical authorities are of the opinion that over 90% of these radiations reach the retina. The iris may absorb 75% to 80% of these radiations. Consequently effects of these rays upon the unprotected eye may be serious – like a sun burn within the eyes. It is, therefore, very necessary to guard the eyes against this radiation.

3.2.3 Exposure to Fumes & Gases

All welding and cutting operations result in the production of a certain amount of smoke and atmosphere contamination. There have been cases where welders, working inside tanks, pipes, tunnels or other confined and badly ventilated places, have fainted. In some of these cases, fumes have been held responsible, whereas the true cause was simple deprivation of air. For this reason, it is desirable to provide means for recovery of these fumes and enhancing ventilation especially when welding takes place in such confined spaces. Fumes can cause symptoms such as nausea, headaches, dizziness, and metal fume fever. The possibility of more serious health effects exists when highly toxic materials, such as, manganese, cadmium, etc., are involved.

The amount and composition of fumes and gases emitted from welding, cutting and allied processes depend upon the composition of the filler metal and base material, welding process, current level, arc length, and other factors. When certain coated or treated metals are welded, dangerous fumes may arise and therefore good ventilation or respiratory protections are required. Special attention must also be paid to ventilation in the welding of non-ferrous metals and contain alloy steels, as well as protection from the hazards of ozone, carbon monoxide and phosgene, which may be formed.

Welding Fumes

All welding processes produce fumes, but the composition and concentration of the fumes can vary widely. Almost all of the fume originates from the filler metal and the coatings contained in the consumable electrodes. The largest component of all welding fumes is iron oxide. Depending on the welding process and the material being welded, the fumes may also contain various combinations of the metals such as aluminium; cadmium; chromium; copper; fluorides; lead; manganese; molybdenum; nickel; tin; titanium; vanadium; and zinc and other chemical compounds. Copper, aluminium, and other metals are occasionally alloyed with beryllium, which is a highly toxic metal. When a metal like this is welded or cut, high concentration of toxic beryllium may result in, shortness of breath, chronic cough, weight loss, fatigue and general weakness. If the metal being welded has been painted or coated with corrosion or rust inhibitors, these coatings may decompose. Welding galvanized steel, for example, generates large amounts of zinc or cadmium in the fume. Welding painted metals may result in high levels of lead fume, if the paint contains lead. Exposure to zinc oxide fumes can lead to a sickness named “metal fume fever” and some cases can be fatal. The greatest concern about potential health effects from welding, centre on cadmium, chromium, iron oxide, nickel, and zinc.

Most welding fumes are very small (less than one thousandth of a millimetre) and so can be easily inhaled. When exposed to these fumes, some fume particles may dissolve in the lungs and be transported by the blood or lymphatic system to other parts of the body, where they may have toxic effects. The potential for health effects from welding fumes depends on the total amount of fume that is inhaled, and the specific toxic metals or compounds present in the fume. The human respiratory system has several ways of removing most of the deposited particles over a period ranging from a few days to many months. Researchers found that even after a lifetime of welding, it is unusual to find more than a few grams of welding fume particles in the lungs of welders.

Welding Gases

The gases generated during welding of unprimed metals include ozone, nitrogen oxides, carbon monoxide, and carbon dioxide. Ozone and nitrogen oxides are formed by the action of ultraviolet radiation from the welding arc. It is difficult to control exposure to these gases because they are formed at a distance of up to several metres from the welding arc. Metal inert gas welding, generates higher levels of ultraviolet radiation than shielded metal arc welding, resulting in the formation of greater amounts of ozone and nitrogen oxides.

Carbon dioxide and carbon monoxide generated by melting of the coatings of consumable electrodes in the high temperatures of the welding arc, may be a health hazard, only if welding is carried out in enclosed or confined spaces with inadequate ventilation. Similarly, if gas shielded arc welding is carried out in enclosed areas with insufficient ventilation, then the shielding gases, such as carbon dioxide or argon, may displace the oxygen in the surrounding air.

The types of gases released are related to the chemicals contained in the coatings. For example, polyurethane coatings may release large amounts of formaldehyde and toluene diisocyanate, whereas welding metals coated with epoxy resins may result in exposure to hydrogen cyanide and carbon monoxide. Degreasing solvents such as, trichloroethylene and perchloroethylene are commonly used to clean metals before welding. Ultraviolet radiation or heat from the welding arc breaks down these compounds to form highly toxic gases such as, phosgene, phosphine, chlorine or hydrogen chloride. Exposure to these gases may also occur if the degreasing process is carried out close to where the welding is done.

Several studies have been done to determine whether long-term exposure to welding fumes and gases may cause lung diseases such as bronchitis, emphysema, and asthma among welders. Some of the studies suggest that welders experience a higher rate of these lung diseases, compared to other workers or the general population. However, other studies have not found such an increase when age, smoking, and exposure to other pollutants, such as asbestos, have been taken into account.

4.0 PROTECTIVE EQUIPMENT

The molten metal has a tendency to pop and spatter, as heat is applied and oxygen reacts with superheated metal. When molten metal or hot particles are emitted, a leather apron should be worn. In cutting operations, leather spats should be worn to prevent hot particles falling into boots or shoes. For protecting the hands against heat spatter, slag, etc. gantlet type of gloves is sufficient, except in the repair of large castings, where an asbestos cloth jacket or an apron and sleeve protection of this material should be worn.

The goggles and/or face shields protect the eyes from sparks and flying hot metal particles. The goggles or face shield use special lenses to protect the eyes from light damage. A variety of lenses are used depending on the type of welding or cutting that needs to be done, the type of material, and the thickness of the material. If protective eye shielding is not used, painful burns can occur on the surface of the eye and could result in permanent damage. The lens used to protect the eye of the operator should meet definite specified standards. In this connection, reference may be made to IS-5983: Specification for Eye Protectors and IS-1179: Specifications for equipment for eye and face protection during welding. Incidentally, Bureau of Indian Standards has published a series of Indian Standards for welding. It may be noted here that protective covers over filter glass should be cleaned as required and replaced when scratched or damaged.

Welding metals treated with primers, paints, or other protective coatings may be a potential source of exposure to toxic gases. When coated or treated metals are welded, appropriate respiratory protection should be worn. Lack of protection from impact, ultraviolet, infrared and blue light caused severe eye strain and eye damage. Today very good eye protection can be found especially for gas welding aluminium that cut the sodium orange flare completely and provides the necessary protection from ultraviolet, infrared, blue light and impact. Therefore proper protection such as welding goggles should be worn at all times.

Though compliance of safety norms and use of personal protective equipment are very important, while carrying out welding operations, a sizable number of workers do not bother to observe the basic safety norms, may be due to lack of awareness on the hazards involved in welding & cutting operations. The safety audit carried out by author of this article at several sites such as factories, workshops, construction sites, etc., PAN India, revealed that many welders carry out welding and cutting operations without observing safety norms (See Fig 06, 07, 08 & 09) and not wearing the required protective gears (See Fig 10), which can be evident from the photos.

5.0 CONCLUSION

Oxy-acetylene welding and arc welding are the two main methods used in welding, cutting and allied processes. The main hazards involved in these operations are fire & explosions and health hazards. Unsafe methods of working and working conditions resulted in a number of backfires and flashfires ultimately resulting in fire and explosions. Suitable firefighting appliances should be placed near to the place where welding operations are carried out.

Lack of protection from ultraviolet and infrared rays caused severe eye strain and eye damage to welders. An eye injury known as “Arc Eyes” affects those who see the arc without correct type of googles.

All welding and cutting operations result in the production of a certain amount of smoke and atmospheric contamination. In most cases these fumes are harmless although sometimes they may be irritating. However, there have been some cases, where welders working inside tanks, pipes, tunnels or other confined and badly ventilated places have fainted.

The fumes and gases released in welding operations are mainly related to the chemicals contained in the coatings. Although there are vast amount of published literature, the question of the effects on health from many years of exposure to welding fumes and gases is still largely unanswered. A definite link between welding and cancer has not been established, although some research suggests an increased risk of lung cancer among stainless steel welders.

Exposures to welding fumes and gases should be controlled as much as possible by following good occupational hygiene practices, such as product substitution, process modifications and ventilation. It is desirable to provide means of good ventilation when welding takes place, especially in confined spaces.

It is also desirable to wear appropriate personal protective equipment such as flash goggles, gloves, aprons, boots, spats, welding helmets, welding hoods, appropriate lenses to filter ultraviolet & infrared rays, etc. during the welding and cutting operations. Lack of awareness by operators and supervisors were also observed for safe welding and cutting operations.

REFERENCES

- Accident Prevention Manual: Engineering & Technology, 12th Edition, Chicago, National Safety Council, 2000.

- American Welding Society – Safety in Welding, Cutting and Allied Processes (ANSI Z49.1), Miami, AWS, 2012.

- Canadian Centre for Occupational Health and Safety – Gas Welding and Cutting (Safety Infogram – D01, D02, D03 & D04), Hamilton, CCOHS.

- Canadian Centre for Occupational Health and Safety – Health effects of welding fumes and gases by Paul Sampara, Hamilton, CCOHS, 1985.

- Encyclopaedia of Occupational Health & Safety – 2 Vols. (Welding and thermal cutting by Lyndon, G.S.) Geneva, International Labour Office, 1998.

- ESAB – Precautions and Safe Practices for Arc Welding, Cutting & Gouging (F-52-529), 2009.

- http://www.technologystudent.com/equip_flsh/acet1.html.

- https://en.wikipedia.org/wiki/Oxy-fuel_welding_and_cutting.

- India, Gas Cylinders Rules, 2005.

- India, The Environmental (Protection) Act, 1986. Allahabad, Law Publications, 1992.

- India, The Factories Act, 1948 with amendment 1987, Mumbai, Labour Law Agency, 2011.

- India, The Maharashtra Factories Rules, 1963 – Bombay, Labour Law Agency, 1994.

- IS-1179:1967 – Specifications for equipment for eye and face protection during welding, New Delhi, Indian Standard Institution, 1967.

- IS-4379:1981 – Identification of contents of industrial gas cylinders, recommends colour for various cylinders, New Delhi, Indian Standard Institution, 1981.

- IS-5983:1980 – Specification for Eye Protectors, New Delhi, Indian Standard Institution, 1980.

- Kletz, Trevor A. – What Went Wrong? 2nd ed., Houstan, Texas, Gulf, 1986.

- Madan Mohan and Nair, R.R. – Personnel Protective Equipment – Non Respiratory (AICTE-CEP Publication – 670), Bangalore, All India Council for Technical Education, 1997.

- Morgan, W.K.C. & Seaton, A. – Occupational Lung Disease, 2nd Ed., Toronto, W.B. Saunders, 1984.

- Nair, R. R. – Safe Handling of Compressed Gases, Industrial Safety Review, March 2012.

- Nair, R. R. – Safe Working in Confined Spaces, Industrial Safety Review, February 2013.

- Nair, R.R. and Others – Safety Audits carried at various factories PAN India, Navi Mumbai, SHIB.

- National Fire Protection Association – Standard for Fire Prevention during Welding, Cutting, and Other Hot Work (NFPA-51B), Quincy, NFPA, 2014.

- National Institute of Occupational Health – Safety & Health in ‘Arc Welding and Gas Cutting’ (Pub: 78-138), Cincinnati, NIOSH, 1978.

- Safety and Fire Protection Handbook, edited by R. Veeraraghavan, 2nd Edition, Mumbai, safe Technology, 2009.

- United Kingdom, Health and Safety Executive – Electric Arc Welding (Safety at Work Series No. 46), London, HMSO.

- United Kingdom, Health and Safety Executive – Safety in gas welding, cutting and similar processes,(05/12 INDG297).

- Zenz, Carl – Occupational Medicine, Chicago, Year Book Medical Publishers, Inc., 1975.

Mr. R. R. Nair has more than 50 years’ experience in Occupational Safety, Health & Fire Protection. He has carried out about 80 projects in SHE Pan India (Safety Audits, Accident Investigations, Environmental Studies, Hazard Identification and Risk Assessment (HIRA), Hazardous Zone Classifications, Fire Safety Audits in High Rise Buildings, etc.). He is author of 15 books and about 75 articles in various topics on SHE.

He can be contacted on:

M: +91 7045172050, Resi: +91 477 2266994

E-mail: ceo@shib.co.in / shib@vsnl.com

Website: www.shib.co.inp

Mr. R. R. Nair has more than 50 years’ experience in Occupational Safety, Health & Fire Protection. He has carried out about 80 projects in SHE Pan India (Safety Audits, Accident Investigations, Environmental Studies, Hazard Identification and Risk Assessment (HIRA), Hazardous Zone Classifications, Fire Safety Audits in High Rise Buildings, etc.). He is author of 15 books and about 75 articles in various topics on SHE.

Mr. R. R. Nair has more than 50 years’ experience in Occupational Safety, Health & Fire Protection. He has carried out about 80 projects in SHE Pan India (Safety Audits, Accident Investigations, Environmental Studies, Hazard Identification and Risk Assessment (HIRA), Hazardous Zone Classifications, Fire Safety Audits in High Rise Buildings, etc.). He is author of 15 books and about 75 articles in various topics on SHE.