The term ‘Water Mist’ refers to fine water sprays in which 99% of the volume of the spray is in drops with diameters less than 1000 microns. The use of the water mist in fire supression, compared to the use of gaseous agents and conventional sprinkler systems, has demonstrated advantages including the following:

- No toxic and asphyxiation problems

- No environmental problems

- Low system cost

- Limited or no water damage, and

- High efficiency in suppressing certain fiires.

Over the last dacade, studies on water mist technology have significantly increased. A survey carried out by Mawhinney and Richardson in 1996 indicated that nearly 50 agencies around the world are involved in the research and development of water mist fire suppression systems, ranging from theoretical investigations inot extinguishing mechanisms and computer modeling to the development, patenting and manufacturing of mist-generating equipment. These recent studies have shown that water mist technologies have the potential either to replace current fire protection techniques that are no longer environmentally acceptable, or to provied new answers to problems where traditional technologies have not been as effective as desired.

In order to identify future developments and potential efficacy improvements for water mist fire suppression systems, there is a need to review the progres that has been made on water mist technology over the last few years. This paper provides a review of the fundamental research in water mist fire suppression systems, including mechanisms of extinguishment, spray characteristics, mehods of generating water mist some factors that infuence performance of water mist, such as the enclosure effect and dynamic mixing, system configuration, Application, Limitation of Water Mist system, Commission and Accepetance test and Guideline Standards.

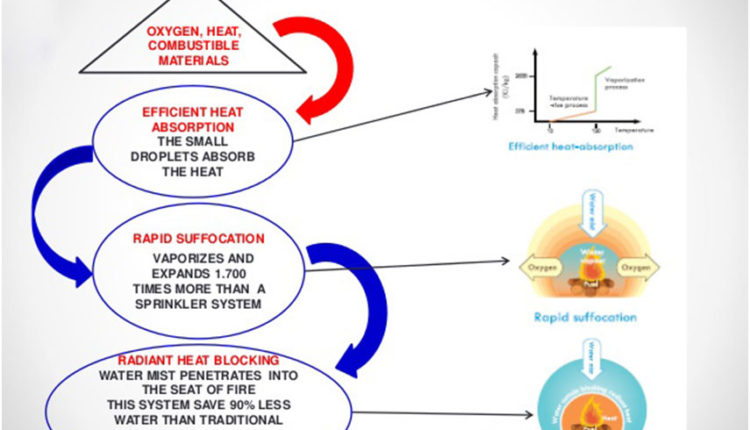

Extinguishing Mechanisms

Wate has favorable physical poperties for fire suppression. Its high heat capacity (4.2 J/g.K) and high latent heat of vaporization (2442 J/g) can absorb a significant quantities of heat from flames and fuels. Water also expands 1700 times when it evaporates to steam, which results in the dilution of the surrounding oxygen and fuel vapors. With the formation of fine droplets, the effectiveness of water in fire suppression is further increased due to the significant increase in the surface area of water that is available for heat absorption and evaporation.

| Droplet Size (mm) | 6 | 1 | 1 |

| Total Number of Droplets | 8.8 x 103 | 1.9 x 106 | 1.9 x 109 |

| Total Surface Area (m2) | 1 | 6 | 60 |

(The Variation of Surface Area of Water with Droplet Size (Volume of Water 0.001m3)

The classification of extinguishing mechanism of water mist in fire suppression as primary and secondary mechanisms, which can be summarized as follows:

Primary Mechanism

Heat Extraction

- Evaporation (heat extraction is a function of surface area of droplets

- Reducing droplet size increases surface area

- Increase in surface area allows for larger cooling effect for a given flow

Oxygen Displacement

- Water converts to vapor expanding by a factor of 1700 times

- Oxygen is displaced and diluted, thereby blocking it form the fuel sources

- Higher heat level causes a faster vaporization

Secondary Mechanism

Radiation attenuation

- Small water droplets tend to remain suspended

- The expanding mist will expand and cool the gases and other fuels in the area

- Blocks the transfer of radiant heat to the adjacent combustibles and pre-wets them

Kinetic Effects

- This is a secondary factor attributed to gas phase cooling and oxygen depletion

- However, it may also increase a fire’s HRR by supplying more oxygen upon the mist’s first contact with the fire

- For this to happen, the fuel evaporation rate has to be intense enough

It is a fact that water mist sprays sometimes extend the time to extinguishment and/or trigger increased flame intensity or ‘flare-ups’. There are various theories. One suggests that the turbulence created by the spray cause more air to the combustion zone. Water mist for explosion suppression is unpredictable: Mist may either invigorate or quell the explosion.

Factors That Affect Water Mist Performance

Water Mist Characteristics

The effectiveness of a water mist system in suppressing a fire is directly related to the spray characteristics produced by the nozzles. Rabash, in his early study, gave a detailed list of the important parameters of water sprays for fire suppression. These are:

- Mean flow rate per unit area in the fire region,

- Distribution of flow rate in and about the fire area,

- Direction of application,

- Droplet size and distribution

- Entrained air velocity, and

- Droplet velocity relative to entrained air, flame velocity and fuel type

Droplet Size Distribution

For a comparison of various defined water droplets:

Technical definition of ‘mist’: 0.01-10 micron

Technical definition of ‘spray’: 10-4000 micron

Smog: 0.01-2 micron

Clouds/fog: 2-70 micron

Mist: 70-200 micron

Mist for Fire Extinguishing, Suppression or Smoke Scrubbing 50-200* micron

Drizzle: 200-500 micron

Rain 500-5000 micron

Sprinkler for Fire Extinguishing and Suppression 500-5000 micron

*Above values are mean diameters. In fire protection mist droplets are defined as Dv0.9 or Dv0.99 <1000 micron. The latter means sprays for which 99 percent of the volume of the spray is contained in droplets less than 1000 microns in diameter.

The above indicate relative drop sizes. However, mist is characterized by a rather wide drop size distribution, i.e. the number or volume of droplets for each given droplet diameter within a spray.

Flux Density

Spray flux density refers to the amount of water spray in a unit volume (Ltr per min /m3) or applied to a unit area (Ltr per min/m2). Neither is good design specifics as spray performance relate more to momentum, cone configuration and subsequent influence by obstructions in spray paths. Most water mist sprays become very uneven or unpredictable, due to interaction with each other and cone shapes.

Spay Momentum

Momentum of water mist is a very important characteristic. It is often decisive of performance in terms of time to extinguish, effective use of water and system reliability. Three factors constitute mist momentum: Velocity, direction and mass. Direction defined relative to fire plume. It has been proven that directionality may be more important than both drop size distribution and mass flow rate of nozzles. Drops size distribution of Dv0.9 200 microns may apparently be equally as effective as 100 microns and vice versa.

Enclosure Effect

Enclosure effects are, contrary to kinetic effects of spray, potentially extremely effective. Water mist easily extinguish large fires relative to room volume and just barely effect small fires. Shielded fires are more or less enclosed, and in some cases the enclosure effect extinguishes them. The enclosure effect is linked to heat from the fire vaporizing water and the vapor being contained and filling the enclosure if not well ventilated.

Dynamic Mixing

During water mist discharge, strong dyanamic mixing is produced in the compartment, as the discharge of water mist entrains surrounding gases and pushes the combustion products and water vapor in the hot layer near the ceiling downward to mix with the gases near the floor of the compartment. The dynamic mixing created by water mist discharge reduces oxygen concentration in the lower portion of the compartment and increase the convective mixing of mist, water vapor and combustion gases near the fir, resulting in the enhancement of the mist’s extinguishing capability. The concentrations (O2, CO2, CO etc) and temperatures throughout the compartment tend to be uniform after water mist discharge.

Additives

For heritage applications additives are generally not wanted and a potential hazard to artifacts, except antifreeze protection in attics and in other rough areas of historic structures. But for the record, sea water mist extinguishes hydrocarbon fire up to 50 % faster than pure water, and substantial increase in performance is gained by just 0.3 % of AFFF additive (no longer readily available). Antifreeze additives may have adverse effects and currently most water mist systems employ the same type of antifreeze (Temper S) as optimum. The Temper-S additive /27/ is found not to add energy to fire and fits water mist applications especially well.

Methods of Generating Water Mist

In general, water mist generating systems can be divided into three basic categories based on the atomizing mechanisms used to produce the fine droplet: impingement nozzles, pressure jet nozzles, and twin fluid nozzles. Any other type of nozzle is a combination of these three basic types.

These three types of nozzles work under different operating pressures and can produce different spray characteristics. NFPA 750 defines three pressure regions for water mist generating technologies and type of system used:

- Low Pressure (<12 bar)

- Intermediate Pressure (12-34 bar)

- High Pressure (>34 bar)

- Deluge (open nozzles)

- Automatic (closed nozzles)

- Hybrid nozzles

Spray Density

Different Water spray density for different type of system as follows:

- Sprinkler Ordinary Hazard: 5.0

- Sprinkler Light Hazard: 2.25

- Residential Sprinkler: 2.05

- Water Mist 0.5-3

- Water Mist Flashover Suppression 0.3-1

- Heavy Rain (weather): 0.1

- Smoke Scrubbing Mist: 0.0

- Fog (weather): 0.0

System Configuration

- Main Control Panel

- Water Pump (For High Pressure Water)

- Fire Detectors ( Detects Fire in Protected Area)

- Solenoid Valve (One For Each Protected Area)

- Water Nozzles ( Produces Water Mist)

- Supply System – storage vessel (e.g. tanks, cylinders), town’s mains, propellant (e.g. nitrogen), and pumps.

- Delivery System- wet pipe system, dry pipe system, pre-action system, deluge system, and pipe (Material e.g. stainless steel, fire rated CPVC plastic, copper, supports)

Application modes of water MIST

Object Application (Local Application)

The water mist system is designed to discharge water on dedicated objects only, within a room.

Room Filling (Total Compartment Application)

The water mist system has nozzles uniformly spread throughout a room, protecting every objects and areas. Most systems are for fire extinguishing or suppression. Room filling is required for flashover suppression.

Zoned Application

As room filling systems, but zoned so that one valve serves a specific part of the protected room. The valve is operated from detection systems. Zoned application must be designed carefully and often becomes complex. Nozzles may be closed (automatic) or open (zoned deluge systems).

Applications

Water mist systems are used for a wide range of performance objectives, including the following:

- Fire extinguishment,

- Fire suppression,

- Fire control,

- Temprature control, and

- Exposure protection.

Typical uses for the systems are as follows:

- Rooms, vaults, enclosed machines, containers, storage tanks and bins.

- Flammable liquid storage and processing areas.

- Engines using flammable fuels.

- Computers, data processing equipment and control rooms.

- Electrical hazards, such as transformers, switches, circuit breakers, and rotating equipment.

- Electronic equipment, including telecommunication equipments.

- Cooking equipment using cooking oils and fats.

- Ship engine bay.

- Aircraft cargo bay, crew and cabin compartment.

A system may be used to protect more than one risk area by means of directional valves. Where two or more areas could be simultaneously involved in a fire by reason of their proximity, such areas shall be protected by either:

- Individual systems designed to allow simultaneous operation; or

- A single system sized and arranged to discharge simultaneously on all potentially involved hazards.

Limitations of Water MIST Systems

The systems shall not be used for direct application to materials that react with water to produce significant amounts of heat or hazardous products. These materials include the following:

- Reactive metals, such as lithium, sodium, potassium, magnesium, titanium, zirconium, uranium and plutonium etc.

- Metal alkoxides, such as sodium methoxide

- Metal amides, such as sodium amide

- Carbides, such as calcium carbide

- Halides, such as benzoyl chloride and aluminium chloride

- Hydrides, such as lithium aluminium hydride

- Oxyhalides, such as phosphorus exybromide

- Silanes, such as trichloromethysilance

- Sulfides, such as phosphorus pentasulfide &

- Cyanates, such as methylisocyanate.

Commissioning & Acceptance Testing

- Spray form Test of Nozzles and Direction of flow of Water mist

- Leak Test

- Performance of System at full pressure and low pressure

- Performance of Pump

- Activation and functional checks of Visible and Audio alarm System in corporate with system

- Air testing of the system

- Approval of Water System

Criteria for Acceptance

The completed water mist system shall be commissioned in accordance with as per Guideline Standards and the system’s performance shall be proven by the following methods:

All pipework that could potentially contain water shall be hydrostatically tested to 1.5 times the normal working pressure for 2h. Any loss shall be determined by a drop in gauge pressure or visible leakage.

The water mist system shall be tested as follows:

- It shall be subjected to full discharge test and the system and supply pressure shall be recorded. Or

- Where a full discharge test is not required by the appropriate authority, provision shall be made to verify the pressure and flow of the water supply and free passage to all nozzles.

On completion of the acceptance procedure, a certificate of compliance shall be issued by the installation contractor.

Guidelines And Standards

Systems are tested and installed in accordance with:

- NFPA 750

- FM 5560

- CEN TS 14972

- IMO standards

- SOLAS Chapter 2-2, Regulation 10.5.6 and 1.2.2.4

- British Standards (Proposed BS DD, Draft EN TS 14972)

- IS 15519 : 2004

Conclusion

The extinguishing mechanisms of water mist system have been identified as: cooling of the fuel and flame, displacement of oxygen and fuel vapor, and radiant heat attenuation, with additional kinetic effects. Although all of these mechanisms are involved to some degree in fire extinguishment, only one or two mechanisms play a dominant role in any specific fire suppression scenario.

Water mist does not behave like a ‘true’ gaseous agent in fire suppression. The effectiveness of a water mist system in fire suppression is dependent on spray characteristics with respect to the fire scenario (shielding of fuel, fire size and ventilation conditions). The other factors, such as the enclosure effect and the dynamic mixing created by the discharge of water mist, also affect water mist performance in fire suppression.

Experience : I am serving in Indian Navy Since last 15 Years and handling various fixed fire fighting (CO2 drenching system, AFFF foam System , Freon Smothering System, Water Mist System, Sprinkling System ect.) and portable fire fighting system including damage control onboard ships and establishments. I am a member of Specialist group during any emergency and exercise onboard ship. My various article as been published in Fire Engineers Magazine (Institute of Fire Engineers).

Qualification : CES, BSc. (Marine Engg), Dip (Industrial Safety), PG Dip (PM & IR), GI’Fire E’